We assist in project planning, project execution and commissioning, optimizing processing equipment and improving production. We create concepts, documents and specifications and offer staff training to improve working skills and motivation.

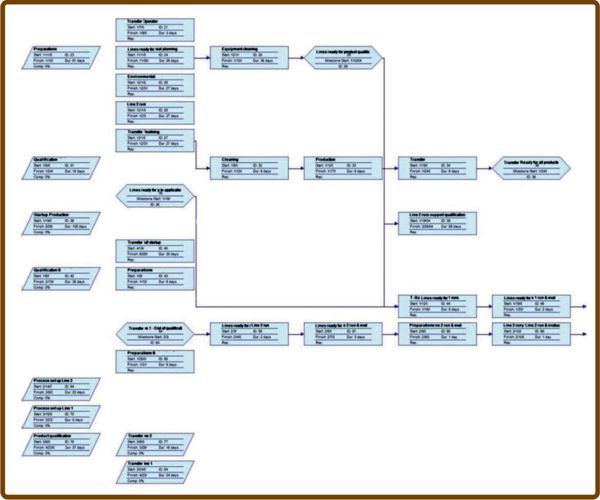

In planning and executing factory projects, it may be beneficial to draw on external expertise to help cover skills/capacity shortages. Our independent and highly specialised experts have a track record of assisting with layout optimization, project planning, project delivery, commissioning and acceptance procedures.

Companies need to make sure that the right technical core processes are in place to maintain product consistency. Thanks to our long standing experience in developing and improving tobacco processing equipment (conditioning, cutting, drying, blending, feeding etc.) we can help you identify the best solutions. Our technical service KPQM (Key Process Quality Maintenance) guarantees long-term consistency of tobacco processing at the highest level.

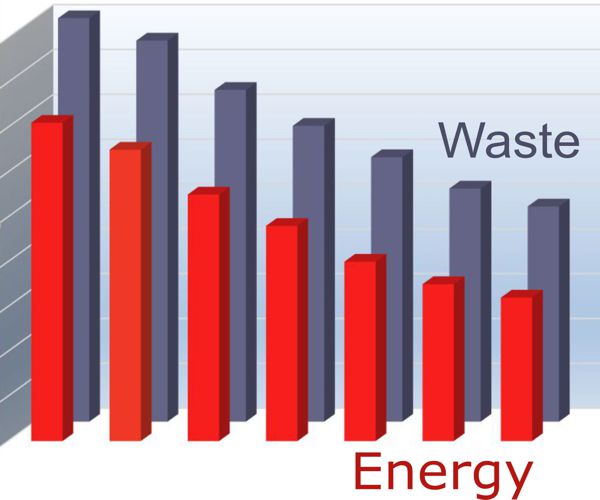

Minimising overall product waste and reducing energy consumption without compromising product quality is a top priority for any company. By taking a close look at all areas of production we can help you identify opportunities for increasing efficiency and securing substantial benefits quickly.

Although tools to increase production efficiency such as OEE, 5S and SMED are widely available, their implementation may prove difficult, requiring a detailed understanding of the intricacies of production processes, a good contact with the shop floor and a pragmatic approach to what may be achievable. Inno.tob has thorough experience in customising tools, identifying bottlenecks and supervising improvement processes on behalf of our customers.

All company policies and decisions need to be supported by reliable technical documents which are clear, well-structured and accurate. Our long-term engagement in the tobacco industry gives us profound experience in assisting with well aligned concepts, technical standards and procedures relevant to the tobacco industry for equipment, automation, procedures and safety.

Skilled and highly motivated people are key to achieving manufacturing excellence. We can help to make it happen – with useful and well-structured training lessons for technicians and operators running key processes such as DCC&C, cutting, expansion, drying, blending and maker feeding. Our process training combines long-term expertise of OEM equipment with practical needs on site.

inno.tob | Hamburg, Germany | Phone +49 - (0)40 - 27 88 49 02 | E-mail info@innotob.com | data protection